In the world of precision engineering, the سنبه پران mandrel stands as a true marvel of craftsmanship. This unassuming tool plays a pivotal role in various industries, from manufacturing to construction, and even in the realm of artisanal craftsmanship. Its ability to shape, trim, and create intricate designs with precision is a testament to human ingenuity and technological advancement.

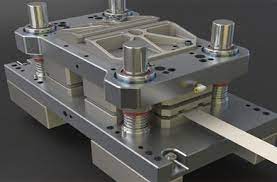

Paragraph 2: The cutting mandrel’s primary purpose is to cut, shape, and refine materials like metal, wood, plastic, and even glass. It consists of a cylindrical rod, often made of high-quality steel, that is equipped with a cutting edge, usually made from tungsten carbide or diamond. This cutting edge is meticulously designed to withstand the rigors of repeated use and to maintain sharpness for extended periods, ensuring consistent and accurate cuts.

Paragraph 3: One of the standout features of the cutting mandrel is its versatility. Whether you’re in a workshop crafting intricate jewelry pieces, on a construction site shaping metal beams, or in a manufacturing facility producing precision parts, the cutting mandrel can adapt to various tasks. Its adaptability is enhanced by the availability of different mandrel sizes and cutting edge designs, allowing professionals to choose the one that best suits their specific needs.

Paragraph 4: Precision is the name of the game when it comes to cutting mandrels. These tools enable artisans and engineers to create flawless, clean cuts, reducing the need for extensive post-processing and enhancing the overall quality of the final product. This precision extends to the mandrel’s ability to work with various materials, making it an indispensable tool in the arsenal of craftsmen and industries alike.